Put on the kettle and get comfortable, cause this post is going to be long. In my last post I wrote that I had booked an appointment to get the final SFRO-approval for my frame. What I hadn't expected was that this final inspection would turn into such a palaver.

Put on the kettle and get comfortable, cause this post is going to be long. In my last post I wrote that I had booked an appointment to get the final SFRO-approval for my frame. What I hadn't expected was that this final inspection would turn into such a palaver.

But before we proceed I thought I’d just take a minute to explain the process of getting what is to all intents and purposes a scratch built framer through the Swedish M.O.T/approval procedure. The Swedish government has outsourced the responsibility for inspecting “amateur built” bikes and cars to an organisation called SFRO. SFRO consists of a small number of Swedish car and bike enthusiasts who, by being fiercely thorough make sure that no dangerous or badly built contraptions reach the streets. And by making sure of that, they protect the hobby from bureaucrats who would like nothing better than to put a stop to our beloved hobby. I just wanted to make that clear from the outset to make sure you don’t get the impression that I in any way have a beef with SFRO. You can see where this is leading now can’t you…?

In order to get a bike like mine approved you first have to get your frame/bike SFRO-inspected in an unpainted state. At this point the welds must be left untouched (i.e. not ground or sanded). This to show that the craftsmanship is up to scratch and that the overall geometry of the frame is sound. I passed that one with flying colours. Next step is to paint and assemble the bike and have the bike noise tested. And as you know, I somehow managed to pass that one too. The third step is where the SFRO inspector actually rides your bike and makes sure that it handles and that the brakes work and so on. If it does, you can then book an appointment to have the bike M.O.T’d and get your official papers and your registration plate.

So, with that in mind, let’s rewind the tape a month or so. I loaded my bike on my rental trailer and drove the 75 clicks to Svedala where I was meeting up with the SFRO guy. I unloaded and the guy complemented my on the looks of the bike, the components and the overall craftsmanship. After taking some measurements he mounted a G-meter on the tank and drove off. He came back after 15 minutes or so and I got compliments on the brake performance. Not surprisingly really since the brakes are a bit oversized, to put it mildly. He then checked the paperwork once more and was just about to put his stamp of approval on the bike when he decided to have one last look on the receipt I got from the place where we bought the frame tubes…

As I may have mentioned, SFRO doesn’t like Cro-Mo tubing, so we decided to opt for regular steel tubes to make sure the bike passed with as little fuss as possible (the bike is so light anyway that it makes little difference on the street). Now, SFRO publishes a book every other year where all construction rules, permitted measurement etc are listed together with a list of all the different kinds of tubing that SFRO prefers. What we didn’t know at the time when we ordered the tubes, was that SFRO, in their latest book (that we didn’t have), had inserted a paragraph where it stated that cold drawn steel tubes should be avoided due to possible problems with brittleness resulting from bending the tubes.

The SFRO-guy looked up from his papers and said in a sombre voice “we have a problem”. He explained the issue and my heart sank. Suddenly my frame was unusable anywhere outside of a racetrack. I loaded the bike up again and thoughts of torching the bike and trailer and leaving it by the roadside to burn went through my head. My wife told me later that I looked completely gutted when I walked through the door.

After a few days of almost clinical depression I got a text from the SFRO-guy where he stated that there was one possibility we could try: a Brinell-test to see if the tubes we had used perhaps would fall within the permitted tolerances after all. He would start looking for the test equipment that was supposed to be somewhere in Sweden. The weeks came and passed. And with them the best part of the Swedish summer. Until finally this week when I got the call: “Can you come to Svedala on Saturday? We have a bit of a SFRO-conference and I have been able to locate the Brinell-test equipment”.

I felt a bit like I was presenting my bike to the Spanish Inquisition as I rolled my framer into the large garage where the SFRO-guys were having their meeting. I was told to leave and come back in two hours. I drove to a press centre and picked up the new PB while I waited for the minutes to tick down.

I hour, 59 minutes and 50 seconds later I pulled into the court yard and was met by “my” SFRO-guy who, not unlike the emperor in “Gladiator” slowly raised his hand in front of him, stuck his thumb out and gave me a slow-motion thumbs up… It passed.

In the image above, you can see where they scratched off the paint in order to test the steel. I guess I will have to repaint the frame, but I’d much rather do that than start all over from scratch!

I know I've said this before: but this time it really is close to finished...

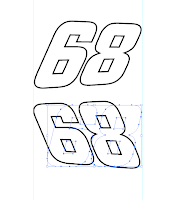

I like italic racing numbers on bikes. They look like they are forced into leaning backwards as the bike accelerates. At least if you view the bike from the left side. The problem is that if you put italic numbers on the right side of the bike – then they lean the wrong way! Not nice. Thankfully there is a workaround. You will need Adobe Illustrator (or another vector graphics application) and a little patience. But it will be worth it.

I like italic racing numbers on bikes. They look like they are forced into leaning backwards as the bike accelerates. At least if you view the bike from the left side. The problem is that if you put italic numbers on the right side of the bike – then they lean the wrong way! Not nice. Thankfully there is a workaround. You will need Adobe Illustrator (or another vector graphics application) and a little patience. But it will be worth it.